Several industries have made motor inverters central to their operations due to the increase in energy efficiency demands and the evolution of industrial automation. A motor inverter, more commonly referred to as a variable frequency drive, is essential for varying the speed, torque, and direction of electric motors. In the manufacturing, HVAC, or electric vehicle industries, selecting the appropriate motor inverter manufacturer has a massive influence on your system’s efficiency, performance, and resilience.

Key Factors to Consider When Choosing a Motor Inverter Manufacturer

1. Advanced Technology and Innovation

The nature of competition in the motor inverters market dictates that the manufacturers are always on the cutting edge of technological advancement. The company should be constantly applying pressure on technological advancement, thereby providing inverters that incorporate current advances in control theories, power electronics, and energy conservation. For instance, an inverter manufacturer that uses intelligent motor control features like sensorless vector control or even adaptive auto-tuning then they shows the commitment they have towards optimizing performance and flexibility.

- Customization Capabilities

Every industry has different demands, and a reliable manufacturer must be able to address unique demands on operations. During customization, they can consider, for example, different voltage ratings, communication ports, or levels of IP protection against dust and water. Manufacturers who provide modular designs or scaled systems demonstrate a recognition of the different requirements across industries.

- Quality and Reliability

Motor inverters are some essential components that, if they fail, could massively result in huge losses or repairs. Thus, the inverter manufacturer has to be well-established and known for the high quality of its products. It is also important to seek manufacturers who observe high-quality standards like ISO 9001-certified inverters with long-lasting service, industrial strength, and real-life performance.

- Energy Efficiency

Energy saving is one of the major advantages of motor inverters, and being a market leader, energy efficiency should be emphasized in the designs of the company. Lobbies like power factor correction, regenerative braking, and energy-saving options are very useful. Furthermore, a good manufacturer will guarantee that their inverters meet global energy classes such as the EU Ecodesign Directive or the US Department of Energy Efficiency for industrial products.

- Global Support Network

A stable support system is critical when selecting a motor inverter manufacturer. Some of the major factors are that the best manufacturers have local service centers, technical service, and replacement part availability for their equipment across the globe. The presence of remote support, online diagnostics, and training for engineers and technicians is also indicative of a manufacturer’s commitment to its customers.

- Compliance and Certifications

Safety and industry regulations must be adhered to when choosing a motor inverter manufacturer. It is crucial to ascertain that the manufacturer’s products are compliant with UL, CE, and RoHS in the region or industry as needed. Such certification ensures the motor inverters are safe and will not harm the environment during its operation making your operations green.

- Ease of Integration

Controllability is another important characteristic of motor inverters since inverters are typically incorporated into more extensive systems. The manufacturer should provide products that are compatible with different PLCs, industrial networks, and SCADA. Compatibility with standard communication protocols such as Modbus, Profibus, Ether, CAT, and others ensures the inverter can easily integrate with your existing system.

- Scalability and Flexibility

While expanding or restructuring your business, so are your operational requirements. A good motor inverter manufacturer should offer systems that can expand in line with the growth of your business. Regardless of whether you want to add more production lines or transform your production environment due to newly adopted energy-efficiency standards, this inverter should provide spots for changes without the need to redo work on the system.

- Cost-Effectiveness

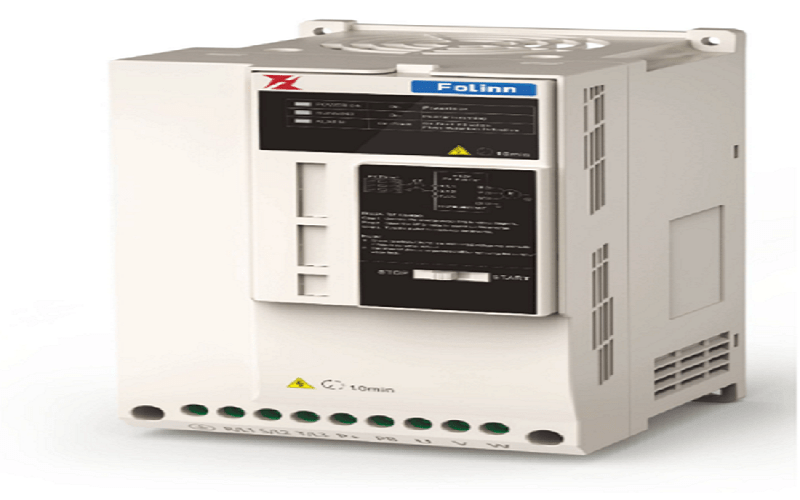

What matters most is the quality and performance, but cost is never out of the equation. To ensure that they are competitive in the market, a leading manufacturer ensures that its prices are low while maintaining the quality of the product. There are the purchase price, energy savings, maintenance costs, and the feasibility of obtaining spare parts when assessing TCO. Follin Drives manufacturers ensure that they produce goods that will meet the client’s needs and at the same time not strain too much by requiring him or her to spend a lot of money at the initial stages.

- Reputation and Case Studies

It is important to note that the reputation of the manufacturer is greatly valued in the industry. Check the comments of other customers and identify those manufacturers who have received positive feedback. Also, verify if they have examples of previous installations done with other companies in similar fields to yours. When choosing a motor inverter manufacturer, it is possible to rely on a reliable manufacturer with a portfolio of completed projects and positive reviews on the equipment.

- Sustainability and Environmental Commitment

Nowadays, sustainability has become not only an advantage but a necessity in various industries. As a growing trend in motor inverter manufacturing industries, it is revealed that there is competition to minimize environmental impacts. This involves the incorporation of environmentally friendly materials in manufacture, minimizing unnecessary material use during manufacture, and developing products that conserve energy.

- Industry-Specific Expertise

Manufacturers with a wealth of experience in specialized industries like automotive and vehicular, oil and gas, food and beverages, and renewable energy have the knowledge that could be vital in handling complex tasks. A motor inverter manufacturer like Follin Drives who is aware of the specific challenges that your industry presents will be in a position to deliver products that can meet stringent legal requirements, operational conditions, and performance levels in the given industry type.

Conclusion

Selecting the right motor inverter manufacturer is a strategic process since it will determine the efficiency, reliability, and effectiveness of an electrical system. To review, the various features include advanced technology, customization, quality, energy efficiency, global support, compliance, ease of integration, scalability, cost, and reputation of the manufacturing company which will help one to select the best manufacturing company.

Thus, although the evaluation of these features can take considerable time and effort, it will ultimately allow you to make a better decision about the system which will not only provide a better performance but also help your business in the long run.

Contact US

Website : Folinndrives »

Address : No.9, 26th Street, Eastern New Area, Wenling, Zhejiang, China.

Email: fuling-daisy@chinafuling.com »

Contact No: 0086 15757626107

Keywords Tags : Frequency converter manufacturer » , Inverter manufacturer » , Variable frequency drive manufacturer » , Drive manufacturer » , ZHEJIANG NEW FOLINN ELECTRIC CO.,LTD » , VFD inverter manufacturer » , variable frequency inverter manufacturer » , Motor Inverter manufacturer » , gerenal inverter manufacturer » , gerenal frequency inverter » , Frequency inverter manufacturer » , Variable frequency drive inverter manufacturer » , dedicated inverter » , dedicated Inverter manufacturer » , solar pump inverter manufacturer » , servo drive » , spindle motor » , smart hoist »